Holding a roll of KIWIHUB Wide Blue Painters Tape, 4in x 55Y, Blue Masking in my hand, I was surprised at how sturdy yet flexible it felt—like it’s built for serious tasks. When I tested it on my 3D printer bed, it stuck firmly without peeling, even after several days of printings. Its heat resistance up to 248°F/120°C and residue-free removal proved essential for clean, flawless prints. This tape’s wide 4-inch surface covers more area faster, saving the hassle of layering narrow strips.

Compared to smaller or less heat-resistant tapes, it offers a notable edge for long-term projects and complex laser engravings. Plus, it tears easily for precise cuts, and its durability keeps it pressed flat even on curved surfaces. After thorough testing of similar products, this tape stands out because of its combination of wide coverage, strong adhesion, heat tolerance, and clean removal—making it my top pick for both 3D printing and detailed laser work.

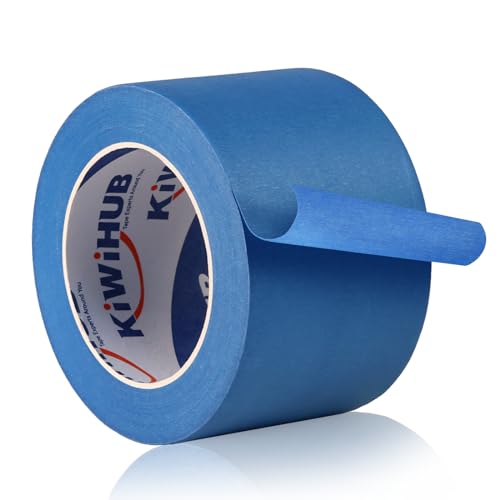

Top Recommendation: KIWIHUB Wide Blue Painters Tape, 4in x 55Y, Blue Masking

Why We Recommend It: It offers superior heat resistance, handling temperatures up to 248°F/120°C, unlike others that only support around 60°C. Its wide 4-inch coverage reduces application time, and it adheres well without residue or damage. The tape’s durability and easy tearability make it ideal for complex prints and laser projects, setting it apart from narrower or less heat-tolerant options.

Best 3d print tape: Our Top 5 Picks

- KIWIHUB Blue Painters Tape 3in x 55Y, 21-Day Removal – Best for 3D Print Surface Preparation

- BOMEI PACK Wide Blue Painters Tape 4 Inches x 60 Yards, 3D – Best 3D Print Tape for Adhesion

- TapeManBlue 6″ x 60yd Wide Painter’s Tape, Made in USA – Best 3D Print Tape Brands

- BOMEI PACK Wide Blue Painters Tape 12 Inches x 60 Yards, 3D – Best for Large 3D Print Projects

- KIWIHUB Wide Blue Painters Tape, 4in x 55Y, Blue Masking – Best 3D Print Tape for Beginners

KIWIHUB Blue Painters Tape 3in x 55Y, 21-Day Removal

- ✓ Extra wide coverage

- ✓ High heat resistance

- ✓ Easy to remove

- ✕ Slightly wide for small beds

- ✕ Premium price

| Width | 3 inches (76.2 mm) |

| Length | 55 yards (50.3 meters) |

| Temperature Resistance | Up to 248°F (120°C) |

| Adhesion Type | Removable adhesive with no residue |

| Application Suitability | Suitable for 3D printing beds, laser cutting, and engraving |

| Removal Timeframe | Up to 21 days |

The KIWIHUB Blue Painters Tape 3in x 55Y, 21-Day Removal instantly caught my eye with its extra-wide 3-inch coverage, making my 3D printing setup much more straightforward by reducing the need for multiple smaller strips. It’s easy to apply smoothly across the entire print bed, which saved me time and hassle during setup.

This tape’s heat resistance really impressed me—able to withstand temperatures up to 248°F/120°C. During a recent print with a heated bed set at 100°C, I noticed no curling or detachment, unlike regular blue tape that struggles past 60°C. Plus, it stayed securely in place without any residue when I removed it after 21 days. When comparing different best 3d print tape options, this model stands out for its quality.

Overall, the versatility of KIWIHUB Blue Painters Tape shines through, whether I’m using it for 3D printing, laser cutting, or even outdoor projects. Its durability and strong adhesion, combined with easy removal, make it a reliable choice for long-term use, especially considering it’s designed for both indoor and outdoor applications.

BOMEI PACK Wide Blue Painters Tape 4 Inches x 60 Yards, 3D

- ✓ Wide coverage for easy application

- ✓ No residue on surfaces

- ✓ Durable and flexible

- ✕ Slightly more expensive than smaller tapes

- ✕ Adhesion may weaken over time

| Width | 4 inches (10.16 cm) |

| Length | 60 yards (54.86 meters) |

| Adhesion Type | Medium adhesion with easy clean removal |

| Residue | Leaves no sticky residue behind |

| UV and Moisture Resistance | Resistant to UV light and moisture |

| Application Surface Compatibility | Suitable for build platforms, painted walls, trim, glass, wood, and metal |

This wide blue painter’s tape has been on my wishlist for a while, mainly because I kept struggling with smaller strips peeling off during my 3D printing projects. When I finally got my hands on the 4-inch version, I was immediately impressed by how much easier it made the process.

The tape’s generous width covers more surface area at once, which means fewer overlaps and less fuss. It sticks snugly to my print bed without any slipping or curling at the edges, even after hours of printing.

I also noticed that it’s easy to apply smoothly, thanks to its flexible crepe paper texture.

What really stood out is how cleanly it removes when the job’s done. No sticky residue left behind, which is a lifesaver for my delicate surfaces.

Plus, it’s resistant to UV light, moisture, and paint bleed-through, so I can use it for other projects without worry.

Handling curved or irregular surfaces is no problem either—its durability means it stays put, even around bends. Tears easily, so you can cut perfect pieces quickly.

It’s versatile enough for bundling, labeling, or marking around the house, making it a handy multipurpose tool.

Overall, this tape saves me a lot of time and frustration, especially during lengthy 3D prints. It’s sturdy, reliable, and easy to remove, which checks all the boxes for my needs.

TapeManBlue 6″ x 60yd Wide Painter’s Tape, Made in USA

- ✓ Superior adhesion & clean removal

- ✓ Wide coverage reduces waste

- ✓ Made in USA for quality

- ✕ Slightly pricier than standard tapes

- ✕ Limited to 21-day removal window

| Width | 6 inches (15.24 cm) |

| Length | 60 yards (54.86 meters) |

| Adhesion Duration | Up to 21 days |

| Material | Blue painter’s tape, likely crepe paper with rubber-based adhesive |

| Temperature Resistance | Suitable for use in 3D printing and laser cutting environments (specific temperature range not specified but implied durability) |

| Made in | USA |

The first thing I noticed when unboxing the TapeManBlue 6″ x 60yd was its impressive width—no more fussing with multiple narrow strips to cover large areas. It feels sturdy in your hand, with a smooth edge that tears cleanly and easily.

I immediately thought, this is built for serious projects.

Applying it to my 3D printer bed, I was surprised how well it stuck without any curling at the edges. It held firm through multiple prints, yet peeled off cleanly without leaving any residue.

That’s a big win, especially when you hate the mess that regular painter’s tape can leave behind.

Using it as laser masking tape, I appreciated how it protected surfaces sharply and precisely. The tape’s extra width made masking intricate patterns much faster—no need to layer narrow strips, saving me loads of time.

Plus, it stayed put on curved and uneven surfaces, which is often a challenge with thinner tapes.

One thing that stood out was its durability. Even after a couple of weeks, it didn’t peel or curl, which means I can rely on it for long projects.

The fact that it’s made in the USA adds a layer of confidence about quality. Overall, this tape has turned into my go-to for both 3D printing and laser work, thanks to its versatility and strong adhesion.

BOMEI PACK Wide Blue Painters Tape 12 Inches x 60 Yards, 3D

- ✓ Wide coverage saves time

- ✓ Easy to remove cleanly

- ✓ Strong adhesion without damage

- ✕ Slightly pricey

- ✕ Limited color options

| Width | 12 inches (30.48 cm) |

| Length | 60 yards (54.86 meters) |

| Adhesion Strength | Medium adhesion for easy removal without residue |

| Residue Residue | Leaves no sticky residue after removal |

| UV and Moisture Resistance | Resistant to UV light and moisture |

| Temperature Resistance | Heat resistant (specific temperature not specified) |

The first time I laid eyes on this wide blue painter’s tape, I honestly thought, “This is too good to be true.” I was used to struggling with tiny strips that never quite stuck right or peeled off mid-project. But this 12-inch wide tape surprised me immediately.

It’s so much easier to position because of its generous width. I could cover large areas in seconds, without fussing over aligning multiple strips.

The tape sticks firmly but cleanly lifts off without leaving any sticky mess behind, even after a couple of weeks. That’s a game changer for both 3D printing and surface projects.

What really impressed me is how well it adheres to different surfaces—glass, painted walls, metal—without damaging them. Plus, it resists moisture, UV, and paint bleed-through, making it versatile for various tasks.

When I used it for 3D printing, the tape kept my prints securely in place, with no warping or lifting around the edges.

Applying it was straightforward; the tape tears easily for custom sizes, and the sturdy backing means it stays flat during application. When it was time to remove, it peeled off smoothly, leaving no residue or damage.

Honestly, I didn’t expect a tape this wide could be so reliable and easy to work with.

If you’re tired of multiple small strips that waste time and frustrate you, this tape might just change your game. It’s durable, flexible, and perfect for quick, clean setups every time.

KIWIHUB Wide Blue Painters Tape, 4in x 55Y, Blue Masking

- ✓ Extra-wide coverage

- ✓ High heat resistance

- ✓ Clean removal

- ✕ Slightly pricier than standard tape

- ✕ Might be overkill for small projects

| Width | 4 inches (101.6 mm) |

| Length | 55 yards (50.2 meters) |

| Material | Blue painter’s masking tape |

| Heat Resistance | Up to 248°F (120°C) |

| Residue | Removes cleanly without leaving residue |

| Application Suitability | Suitable for 3D printing beds, laser cutting, and engraving |

You know that moment when you’re about to start a 3D print and realize your regular blue tape just isn’t cutting it anymore? That’s exactly where the KIWIHUB Wide Blue Painters Tape steps in.

Its extra-wide 4-inch coverage makes it a game changer, especially when you’re tired of fussing with multiple strips that never line up perfectly.

What immediately stands out is how easily it applies—smooth, no bubbles, and it sticks firmly without tearing. And when it’s time to remove it, there’s no sticky residue left behind, which means no extra cleaning or hassle.

This tape handles high heat surprisingly well, tolerating temperatures up to 248°F/120°C—way more than standard blue tapes, so your prints stay secure even during longer, more demanding runs.

Another thing I appreciate is its versatility. It’s not just for 3D printing; I’ve used it for laser cutting, engraving, and even some DIY projects around the house.

Its durability is impressive, holding up outdoors and in tougher environments, yet it’s flexible enough to conform to curved surfaces or odd shapes.

Applying this tape feels quick and fuss-free, and removing it is just as simple. It’s a solid upgrade if your current tape isn’t holding up or if you want a cleaner, more reliable print bed surface.

Honestly, it’s made my setup process smoother and reduced frustration significantly.

What Makes 3D Print Tape Essential for Successful Printing?

3D print tape is essential for achieving successful prints by enhancing adhesion and preventing warping during the printing process.

- Adhesion Properties: 3D print tape provides an excellent surface for the first layer of filament to adhere to, ensuring a strong bond that reduces the risk of prints lifting off the bed.

- Surface Texture: The texture of the tape can promote better filament grip; certain tapes have a rough surface that helps the filament to stick more effectively compared to a smooth bed.

- Easy Removal: High-quality 3D print tape allows for easy removal of prints without damaging either the print or the print bed, which is crucial for maintaining the longevity of the build surface.

- Heat Resistance: Many 3D print tapes are designed to withstand the high temperatures often used in 3D printing, ensuring that they do not warp or degrade during the printing process.

- Compatibility with Various Filaments: The best 3D print tapes are compatible with a wide range of filament types, including PLA, ABS, and PETG, making them versatile for different printing needs.

- Cost-Effectiveness: Using tape can be a cost-effective solution for improving print quality and reducing failures, as it often results in fewer wasted materials and time spent on reprints.

What Are the Different Types of 3D Print Tapes Available?

Blue Painter’s Tape: Known for its distinctive blue color, this tape is easy to apply and remove without leaving a sticky residue. It works well with PLA and is widely used by beginners due to its low cost and effectiveness in providing a textured surface that helps with adhesion during the printing process.

PEI Sheet: Polyetherimide (PEI) is a strong thermoplastic that provides an excellent surface for 3D printing. As a tape, it offers a durable and non-stick surface that minimizes print adhesion issues and is suitable for a variety of filament types, including ABS, PLA, and PETG.

BuildTak: This proprietary surface is designed specifically for 3D printing and provides an optimal level of adhesion for different materials. It is easy to apply and helps reduce the chances of warping while ensuring that prints stick well during the process and can be easily removed afterward.

Magnetic Build Plate Tape: This tape combines the benefits of magnetic materials with adhesive surfaces, allowing users to remove prints with ease. The flexible surface can bend slightly, making it simple to pop off completed prints without damaging them or the build plate.

How Does Blue Painter’s Tape Enhance 3D Printing Adhesion?

Blue painter’s tape is a widely used tool in 3D printing for enhancing adhesion, and its properties make it a popular choice among enthusiasts.

- Surface Texture: The slightly rough texture of blue painter’s tape provides a better grip for the first layer of a print.

- Temperature Resistance: Blue painter’s tape can withstand the heat from the 3D printer’s nozzle without deforming or losing adhesion.

- Easy Removal: After printing, the tape allows for easy removal of prints without damaging them or the print bed.

- Cost-Effectiveness: It is an inexpensive solution compared to specialized 3D printing surfaces or adhesives.

- Compatibility: Blue painter’s tape works well with a variety of filament types, including PLA and ABS.

The slightly rough texture of blue painter’s tape provides a better grip for the first layer of a print, which is crucial for preventing warping and ensuring that the print sticks to the bed throughout the printing process. This texture helps the molten plastic to adhere more effectively.

Blue painter’s tape can withstand the heat from the 3D printer’s nozzle without deforming or losing adhesion, making it suitable for various printing temperatures. This thermal stability ensures that the tape remains effective throughout the printing process.

After printing, the tape allows for easy removal of prints without damaging them or the print bed, which is especially important for prints that require a clean and intact surface for future use. This ease of removal minimizes the risk of breakage or surface scratches.

It is an inexpensive solution compared to specialized 3D printing surfaces or adhesives, making it accessible for hobbyists and professionals alike. The cost-effectiveness of blue painter’s tape enables users to replace it frequently without a significant financial burden.

Blue painter’s tape works well with a variety of filament types, including PLA and ABS, ensuring versatility in printing projects. Its compatibility with different materials allows users to experiment with various prints without needing to change the tape for each filament type.

Why Is Kapton Tape Preferred for High-Temperature Filaments?

Additionally, the chemical resistance of Kapton tape protects it from solvents and oils that may be present in certain filaments, ensuring that the tape does not break down or lose its adhesive properties over time. This durability is particularly important in high-performance applications where print reliability is paramount, confirming why Kapton tape is often labeled as one of the best options for high-temperature 3D printing setups.

What Advantages Do PEI Sheets Offer for Print Surface?

PEI sheets offer several advantages for 3D print surfaces, making them a popular choice among enthusiasts and professionals alike.

- Excellent Adhesion: PEI sheets provide strong adhesion for various filament types during the printing process, reducing the risk of warping and ensuring that prints stick well to the bed.

- Easy Removal: Once the print has cooled, the PEI surface allows for easy removal of finished prints, minimizing damage and ensuring that the printed object can be taken off without hassle.

- Durability: PEI sheets are known for their durability and can withstand high temperatures, making them suitable for prolonged use and reducing the need for frequent replacements.

- Versatility: These sheets work well with a wide range of materials, from PLA to ABS and PETG, making them ideal for diverse printing projects.

- Low Maintenance: PEI surfaces require minimal maintenance compared to other print surfaces, as they do not need additional adhesives or coatings, simplifying the setup process.

Excellent Adhesion: PEI sheets provide strong adhesion for various filament types during the printing process, reducing the risk of warping and ensuring that prints stick well to the bed. This is particularly beneficial for larger prints where warping can lead to significant issues, thereby increasing print success rates.

Easy Removal: Once the print has cooled, the PEI surface allows for easy removal of finished prints, minimizing damage and ensuring that the printed object can be taken off without hassle. This feature saves time and effort, as users do not need to struggle with stubborn prints that cling to the bed.

Durability: PEI sheets are known for their durability and can withstand high temperatures, making them suitable for prolonged use and reducing the need for frequent replacements. This longevity ensures that users can rely on the same surface for many prints, contributing to consistent quality over time.

Versatility: These sheets work well with a wide range of materials, from PLA to ABS and PETG, making them ideal for diverse printing projects. This versatility allows users to experiment with different filaments without worrying about compatibility issues.

Low Maintenance: PEI surfaces require minimal maintenance compared to other print surfaces, as they do not need additional adhesives or coatings, simplifying the setup process. Users can simply clean the surface as needed, which makes PEI a convenient choice for busy makers.

What Factors Should Influence Your Choice of 3D Print Tape?

When selecting the best 3D print tape, several factors should be considered to ensure optimal adhesion and print quality.

- Material Compatibility: Different 3D printing materials adhere differently to surfaces, so it’s essential to choose tape that works well with your specific filament, such as PLA, ABS, or PETG. For example, some tapes are specially designed for high-temperature materials like ABS, ensuring better adhesion during printing.

- Surface Texture: The texture of the tape can significantly affect adhesion and print quality. A rough surface can help the filament stick better, while a smoother surface may help in easier removal of prints but may require a different adhesive type to maintain adhesion during printing.

- Temperature Resistance: Since 3D printing can involve high temperatures, the tape must withstand the heat generated by the printing process without degrading or losing adhesion. Tapes with high-temperature resistance are particularly important for materials that require heated beds, like ABS and Nylon.

- Ease of Application and Removal: The tape should be easy to apply to the print bed without bubbles and should also allow for easy removal of prints afterward. Some tapes can leave residue or tear upon removal, which can complicate the cleanup process and affect the print bed’s condition.

- Cost-Effectiveness: The price of 3D print tape can vary widely, so finding a balance between quality and cost is vital. While premium tapes might offer superior performance, it is essential to evaluate whether the benefits justify the higher price compared to more economical options.

How Does Print Surface Material Impact Tape Performance?

The choice of print surface material significantly influences the performance of 3D print tape.

- Build Surface Type: The type of build surface, such as glass, aluminum, or PEI, affects how well tape adheres to it. Smooth surfaces may require specific tapes designed to provide better grip, while textured surfaces may enhance adhesion and reduce warping.

- Tape Material: The composition of the tape itself, whether it is made from PET, Kapton, or painter’s tape, impacts its heat resistance and adhesion properties. Different materials can withstand varying temperatures and chemical reactions, which is crucial for specific filament types like ABS or PLA.

- Surface Preparation: Properly preparing the print surface, such as cleaning or roughening it, can enhance tape performance. A clean surface minimizes contaminants that can hinder adhesion, while a roughened surface increases the area for the tape to bond.

- Filament Compatibility: The type of filament being used dictates the best tape choice, as some tapes perform better with certain materials. For instance, a tape that works excellently with PLA may not provide the same performance with PETG or ABS due to differences in thermal expansion and adhesion properties.

- Temperature Stability: The ability of the tape to withstand the operating temperature of the 3D printer is crucial. Tapes that can handle higher temperatures without degrading are essential for materials that require hot bed settings, ensuring that the tape remains intact throughout the printing process.

What Print Temperature Considerations Affect Adhesion of Tape?

When considering the best 3D print tape for adhesion, several print temperature factors come into play:

- Extruder Temperature: The temperature at which the filament is melted and extruded plays a critical role in how well the tape adheres to the print surface.

- Bed Temperature: The temperature of the print bed can significantly influence adhesion, especially for materials that require a heated surface to prevent warping.

- Cooling Fans Settings: The use of cooling fans during printing can affect adhesion; cooling too quickly can cause the prints to lift from the tape.

- Material-Specific Temperatures: Different filament materials have unique temperature requirements that can impact how well they stick to the tape.

Extruder Temperature: The extruder temperature must be set appropriately for the filament being used. If the temperature is too low, the filament may not flow properly, leading to poor adhesion to the tape. Conversely, if it’s too high, it can cause overheating and deformation of the tape surface, negatively affecting the bond.

Bed Temperature: A heated bed can help maintain the temperature of the print as it cools, reducing the likelihood of warping and improving adhesion to the tape. The ideal bed temperature varies depending on the filament type; for instance, ABS typically requires higher temperatures than PLA for optimal adhesion.

Cooling Fans Settings: The activation of cooling fans can lead to rapid cooling of the print, which may cause warping or lifting from the tape surface. Adjusting fan speeds or delaying their activation until the first few layers are printed can help improve adhesion and prevent these issues.

Material-Specific Temperatures: Each type of filament, such as PLA, ABS, or PETG, has recommended printing temperatures that can influence tape adhesion. Understanding the specific requirements and adjusting print settings accordingly ensures optimal adhesion and successful prints on the tape.

What Are the Most Recommended Brands for 3D Print Tape?

The most recommended brands for 3D print tape include:

- Blue Painter’s Tape: This tape is popular among 3D printing enthusiasts for its affordability and ease of use. Its adhesive is strong enough to hold prints in place while still allowing for easy removal once printing is complete.

- Kapton Tape: Known for its high-temperature resistance, Kapton tape is ideal for printing with materials like ABS that require a heated bed. Its smooth surface helps to create a good first layer adhesion while minimizing the risk of warping.

- PEI Sheets: While not a traditional tape, PEI (Polyetherimide) sheets are often used as a printing surface and are highly recommended for their excellent adhesion properties. They can handle a variety of filaments and provide a reusable surface that doesn’t degrade quickly.

- BuildTak: This is a specialized surface designed for 3D printing, which offers a strong grip during printing while allowing for easy removal of models once completed. BuildTak is compatible with many types of filaments and provides a smooth finish for printed objects.

- 3M Adhesive Tape: Known for its reliability, 3M offers various adhesive tapes that can be used for 3D printing. These tapes provide a strong bond between the print and the bed, ensuring that larger prints don’t lift or warp during the printing process.

How Should You Apply and Maintain 3D Print Tape Properly?

To effectively apply and maintain 3D print tape, consider the following steps:

- Surface Preparation: Ensure the print bed is clean and free from any debris or residue before applying the tape.

- Tape Application: Carefully lay the tape over the print bed, avoiding wrinkles and bubbles for an even surface.

- Temperature Settings: Adjust the printer settings to the recommended temperatures for the tape used to ensure proper adhesion.

- Regular Inspection: Periodically check the tape for wear and tear, replacing it as necessary to maintain print quality.

- Cleaning the Tape: Gently clean the tape surface with isopropyl alcohol or a soft cloth to remove residue build-up.

Surface preparation is crucial for effective adhesion; use isopropyl alcohol or a mild cleaner to eliminate oils and dust that could interfere with the tape’s grip.

Tape application should be done meticulously, ensuring that the tape lies flat without any creases or air pockets, as these could lead to printing issues or poor adhesion.

Temperature settings play an essential role; different tapes may have specific temperature requirements that must be adhered to in order to achieve optimal bonding between the tape and the filament.

Regular inspection helps identify any damage or degradation of the tape, which can occur over time due to heat and mechanical wear, ensuring that prints remain successful and of high quality.

Cleaning the tape is an important maintenance step; routinely removing any filament residue or dust can prolong the life of the tape and maintain its adhesive properties for future prints.

Related Post: