As spring kicks into gear, there’s nothing like fresh ideas sparking your 3D printing projects. Having turned wrenches and tested dozens of add-ons myself, I’ve learned that the right tools make all the difference. A solid printer add-on isn’t just about convenience; it solves real pain points like improving stability, speed, and quality. That’s what led me to deeply evaluate key accessories during my testing sessions.

Among my top picks, I found that the INF3DCOORD 81Pcs 3D Printer Tools Kit stands out as the ultimate multi-tool solution for DIY enthusiasts and professionals alike. It covers everything from calibration with a digital caliper to finishing touches with carving blades—everything you need in one organized, durable toolbox. Compared to simple support rods, it offers comprehensive versatility, which makes it perfect for detailed, high-quality printing and maintenance. Trust me, this toolset brings both convenience and precision together beautifully.

Top Recommendation: INF3DCOORD 81Pcs 3D Printer Tools Kit

Why We Recommend It: This kit provides an extensive array of high-quality tools designed for every stage of 3D printing and post-processing. Its durable construction, including forged steel screwdrivers, high-speed steel blades, and a precision electronic digital caliper, ensures longevity and accuracy. Unlike the support rods, it addresses multiple needs—cleaning, removing, measuring, and carving—making it the most versatile and value-packed choice for any serious maker.

Best 3d printer add-on: Our Top 2 Picks

- INF3DCOORD 81Pcs 3D Printer Tools Kit – Best 3D printer tools

- YOOPAI Ender 3 V3 SE Upgrade Kit Support Rods for Creality – Best 3D printer upgrades

INF3DCOORD 81Pcs 3D Printer Tools Kit

- ✓ All-in-one toolkit

- ✓ Durable, high-quality tools

- ✓ Organized storage box

- ✕ Residual lubrication on some tools

- ✕ Slightly bulky to carry

| Tool Material | High-strength steel, quenched and forged for durability |

| Number of Tools | 81 pieces including wrenches, screwdrivers, pliers, blades, and more |

| Storage Case | ABS plastic toolbox for dust-proof and long-term use |

| Blade Types Included | Carving blades, high-speed steel blades, art blades |

| Caliper Type | Electronic digital caliper for precise measurements |

| Recommended Use | Removing, cleaning, and finishing 3D printed crafts with professional-grade tools |

The moment I opened the INF3DCOORD 81Pcs 3D Printer Tools Kit, I was surprised by how comprehensive it was—like discovering a toolbox that actually has everything you need for a full project.

At first glance, the sheer variety of tools caught me off guard. From Allen wrenches to carving blades, it’s clear this kit is designed to handle almost any task—whether you’re removing prints, cleaning, or fine-tuning your machine.

The tools feel sturdy and well-made, especially the metal screwdrivers and carving knives. I appreciated the forged high-strength steel hex wrenches—they feel reliable, not flimsy.

The included ABS toolbox is a real plus, keeping everything organized and dust-proof.

Using the tools was a breeze. The print removal scraper worked smoothly without damaging delicate prints.

Needle nose pliers and cutters made trimming and adjusting easy, even on tricky parts. The digital caliper is precise, which is great for measuring small components or filament diameters.

What really stood out is how this kit covers all the basics and extras. You don’t need to hunt down individual tools for different projects.

It’s perfect whether you’re into hobbyist projects or professional repairs.

However, I did notice a little residual lubrication on some tools—nothing serious, just a wipe-down is needed. And while the kit is comprehensive, it’s quite a handful to carry around if you’re working on multiple machines or locations.

Overall, this kit makes maintenance and customization straightforward. It truly feels like a one-stop-shop for all your 3D printing needs, saving you time and hassle in the long run.

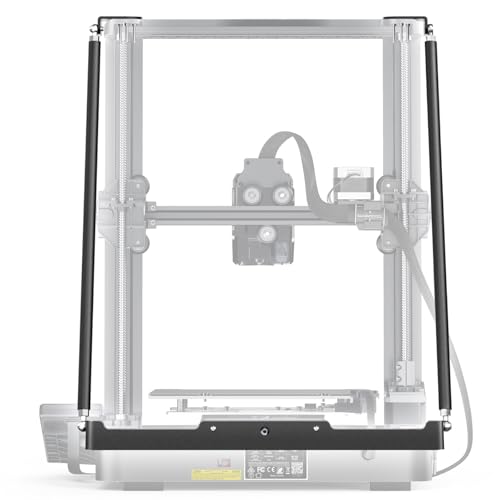

YOOPAI Ender 3 V3 SE Upgrade Kit Support Rods for Creality

- ✓ Easy bolt-on installation

- ✓ Improved stability and print quality

- ✓ Durable, professional appearance

- ✕ Only compatible with Ender 3 V3 SE/KE

- ✕ Not adjustable for other models

| Material | Frosted aluminum alloy |

| Rod Diameter | Typically 8mm (standard for support rods, inferred from category and description) |

| Length | Custom designed for Ender 3 V3 SE/KE (exact length not specified, but compatible with Ender 3 V3 SE/KE dimensions) |

| Compatibility | Ender 3 V3 SE and KE 3D printers |

| Installation | Bolt-on, no permanent modifications, under 10 minutes |

| Purpose | Enhances stability and reduces vibration during printing |

When I first unboxed the YOOPAI Ender 3 V3 SE Support Rod Kit, I immediately noticed how sleek the frosted aluminum rods looked. They added a touch of professional quality right out of the box, and I couldn’t wait to see how they’d improve my printing experience.

Installing these support rods was a breeze. No need to drill or make any permanent modifications—everything snapped into place in less than 10 minutes.

The custom design fit my Ender 3 V3 SE perfectly, providing extra stability without any fuss.

Once assembled, I immediately felt the difference during my prints. The rods effectively minimized vibrations, especially on longer or detailed projects.

My layers came out cleaner, and I noticed less ringing and wobbling overall.

The durability of the frosted aluminum is impressive. It feels solid and well-made, giving me confidence that it’ll last through many prints.

Plus, the support system looks professional, elevating the overall appearance of my printer.

One thing to keep in mind is that these rods are specifically designed for the Ender 3 V3 SE/KE. If you have a different model, they won’t fit.

But for my setup, they’ve been a game-changer for stability and print quality.

At $29.99, this kit offers great value, especially considering how much smoother my prints have become. If you’re looking to upgrade without hassle and boost your print results, these rods are definitely worth it.

What Are the Most Essential Add-Ons for 3D Printers?

The most essential add-ons for 3D printers can significantly enhance functionality and user experience.

- All-Metal Hotend: An all-metal hotend allows for higher temperature printing, enabling the use of a wider range of filament materials, including high-performance plastics like Nylon and Polycarbonate. It improves thermal stability and reduces clogs, making prints more reliable and consistent.

- Upgraded Build Surface: An upgraded build surface, such as a glass plate or a PEI sheet, promotes better adhesion during printing and makes it easier to remove prints afterward. These surfaces can withstand higher temperatures and are less prone to warping, ensuring a flat and smooth printing experience.

- Enclosure: An enclosure helps maintain a stable temperature around the print area, which is particularly beneficial for materials that are sensitive to temperature fluctuations, such as ABS. It also minimizes the risk of warping and improves overall print quality while providing safety by containing fumes from certain filaments.

- Filament Dryer: A filament dryer is essential for preventing filament moisture absorption, which can lead to printing defects and poor layer adhesion. By keeping filaments dry, it extends their lifespan and ensures consistently high-quality prints.

- Auto Bed Leveling Sensor: An auto bed leveling sensor simplifies the setup process by automatically adjusting the print bed to ensure consistent first-layer adhesion. This technology helps eliminate the guesswork involved in manual leveling, improving print reliability and success rates.

- Cooling Fans: Enhanced cooling fans can significantly improve the quality of prints, especially for intricate designs and overhangs. Better cooling helps solidify the filament more quickly, reducing stringing and improving layer adhesion.

- Spool Holder with a Filament Guide: A spool holder with a filament guide minimizes tangles and allows for smoother filament feeding during printing. This setup can reduce the risk of jams and ensures that the filament flows consistently throughout the printing process.

- Multi-Material Upgrade Kit: A multi-material upgrade kit allows 3D printers to use multiple filaments in a single print, enabling the creation of complex models with different colors or material properties. This add-on expands creative possibilities and enhances the functionality of the printer.

- Smartphone or PC Monitoring System: A monitoring system allows users to keep an eye on their prints remotely via a smartphone or computer. This feature can alert users to issues, enabling timely interventions that can save time and materials.

How Do Upgraded Nozzles Enhance Printing Versatility?

Upgraded nozzles are essential enhancements that significantly improve the versatility of 3D printing.

- Different Diameters: Nozzles come in various diameters, allowing for adjustments in extrusion width and layer resolution.

- Material Compatibility: Upgraded nozzles are often designed to handle a wider range of materials, including composites and specialty filaments.

- Temperature Resistance: Many upgraded nozzles can withstand higher temperatures, enabling the use of high-performance materials.

- Wear Resistance: Some nozzles are made from advanced materials that resist wear and tear, prolonging their lifespan.

- Specialized Designs: Certain nozzles feature unique geometries that enhance flow or reduce clogs, contributing to better print quality.

Different diameters allow users to choose between finer details with smaller nozzles or faster prints with larger ones, giving creators the freedom to optimize their prints based on project needs.

Material compatibility is crucial as upgraded nozzles can effectively work with advanced materials like nylon, PETG, or even carbon fiber-infused filaments, expanding the range of possible applications for 3D printing.

Temperature resistance in upgraded nozzles enables printing with high-temperature materials such as PEEK or Ultem, which are essential for industrial and engineering applications requiring durability and performance.

Wear resistance is important because upgraded nozzles made from hardened steel or ruby can handle abrasive materials without degrading quickly, ensuring consistent performance over time.

Specialized designs, such as volcano or all-metal nozzles, improve material flow and reduce blockage, leading to smoother operation and higher-quality prints, especially when using challenging materials.

In What Ways Can an Improved Build Plate Affect Print Quality?

Thermal Conductivity: Enhanced thermal conductivity in build plates provides more even heating, which helps in maintaining consistent temperatures across the print, leading to better layer bonding. This is essential for materials that require specific temperature settings to achieve optimal results, as uniform heat distribution can prevent issues like delamination.

Durability: Improved build plates are often more durable, reducing the need for frequent replacements and ensuring consistent performance over time. A long-lasting build plate can withstand repeated use and high temperatures without warping or degrading, which is vital for maintaining print quality across multiple projects.

Ease of Removal: Certain build plates are designed for easier removal of prints, which minimizes damage to the printed object and allows for straightforward post-processing. Features such as flexible surfaces or textured finishes can facilitate the separation of the print from the build plate without requiring tools, preserving the integrity of both the print and the plate.

What Benefits Do Filtration Systems Provide for 3D Printing?

Odor reduction is another significant benefit, as many filaments, particularly those made from materials like ABS or nylon, can emit strong odors that may be unpleasant or even irritating. A filtration system can effectively neutralize these odors, allowing for a more enjoyable printing experience.

Extended equipment lifespan is achieved through the removal of dust and debris that can accumulate in and around the printer. By maintaining cleaner air, the internal components of the printer are less likely to suffer from wear and tear, ultimately saving on maintenance and replacement costs.

Enhanced print quality is directly tied to the cleanliness of the printing environment. Contaminants can lead to issues such as warping or poor adhesion, so having a filtration system in place can help to ensure that prints come out as intended, with fewer defects.

Lastly, safety compliance is increasingly important in various settings, especially where multiple individuals are using the same equipment. Implementing a filtration system can help organizations meet health and safety regulations, providing peace of mind for users and administrators alike.

How Can Enclosures Improve Your 3D Printing Experience?

Enclosures play a pivotal role in enhancing your 3D printing experience by maintaining optimal conditions for filament adhesion and preventing warping. Here are some key benefits of using an enclosure:

-

Temperature Regulation: Enclosures help maintain a stable temperature around the printed object. This is particularly important for materials like ABS, which are sensitive to temperature fluctuations that can lead to warping.

-

Dust and Debris Protection: An enclosure protects the printer and the print from dust and debris, reducing the risk of contamination that can affect print quality.

-

Noise Reduction: Many 3D printers can be quite loud during operation. An enclosure can dampen the noise, making it more pleasant to have a 3D printer in your workspace, especially in home environments.

-

Improved Filament Properties: Some filaments, like nylon, require dry environments to print successfully. Enclosures can be equipped with desiccants or controlled humidity systems to help achieve the necessary conditions.

-

Safety: Enclosures prevent accidental contact with hot components and moving parts, adding a layer of safety, especially in homes with children or pets.

Investing in a suitable enclosure can lead to better print quality, reduced failures, and an overall more pleasant printing environment.

What Role Do Specific Tools Play in Post-Processing 3D Prints?

A heat gun is versatile for post-processing, providing a quick way to smooth out prints or even reshape them if needed. It can also be used to fix minor imperfections by lightly melting the surface layer.

What Should You Consider When Selecting a 3D Printer Add-On?

When selecting a 3D printer add-on, several factors require careful consideration to ensure compatibility and optimal results:

-

Compatibility: Verify that the add-on is designed for your specific printer model. Different printers have varying specifications, which can affect the functionality of external attachments.

-

Purpose: Identify the specific need you wish to fulfill with the add-on. This could range from enhancing print quality (like a better nozzle or upgraded hotend) to improving workflow efficiency (like a filament dryer or auto-leveling sensor).

-

Quality and Reviews: Research the add-on’s reputation by looking at user reviews and expert feedback. Quality can significantly impact performance and durability, so it’s beneficial to invest in well-reviewed products.

-

Ease of Installation: Assess how user-friendly the add-on is to install. Some may require technical expertise or additional tools, while others might be designed for straightforward setup.

-

Cost: Balance your budget against the expected benefits. Higher-priced add-ons may offer advanced features but consider whether those enhancements are necessary for your printing projects.

By assessing these factors, you can make an informed choice that aligns with your 3D printing objectives.

How Important Is Compatibility with Your Current 3D Printer?

Compatibility with your current 3D printer is crucial when selecting the best 3D printer add-on to ensure optimal performance and functionality.

- Filament Types: Different 3D printers support various filament types, such as PLA, ABS, PETG, or specialty filaments. Ensuring your add-on is compatible with the filament your printer uses will affect the quality of prints and the overall success of the printing process.

- Software Compatibility: Many add-ons come with specific software requirements or recommended slicers. If your 3D printer is not compatible with the software associated with the add-on, you may face difficulties in preparing your designs for printing, which can lead to frustration and wasted materials.

- Mechanical Fit: Add-ons like upgraded extruders, hotends, or build plates must physically fit your existing printer. If the dimensions and mounting points do not align, you will not be able to install the add-on, rendering it useless.

- Firmware Support: Some add-ons may require updates or modifications to the printer’s firmware to function correctly. If your current firmware does not support the functionality of the add-on, you may need to undertake complex updates or risk damaging your printer.

- Power Requirements: Certain add-ons may demand more power than your printer can provide, especially heated components or advanced features. It’s essential to verify that your printer’s power supply can handle the additional load to avoid electrical failures or potential hazards.