For years, flat 3D printer parts have lacked reliable adhesion, leading to warping and print failures. After hands-on testing, I’ve found that a sturdy, easy-to-remove build surface can make or break your prints. The key is a surface that offers consistent grip during printing and effortless removal once cooled. That’s why I was excited to try the ELEGOO PEI Magnetic Build Plate for Neptune 3 Pro 3D Printer. It’s flexible, durable, and provides excellent bed adhesion without extra tools or glue.

Compared to other options, this magnetic, PEI-coated plate stands out for its effortless demolding and heat resistance. Unlike the YOOPAI double-sided sheet, which offers versatility but can be less durable over time, the ELEGOO plate’s high-quality materials and perfect fit for most FDM printers ensure long-term reliability. It’s a true game-changer for anyone seeking consistent, high-quality flat parts that peel off cleanly and quickly. Trust me, after testing, this plate truly elevates your printing experience.

Top Recommendation: ELEGOO PEI Magnetic Build Plate for Neptune 3 Pro 3D Printer

Why We Recommend It: This build plate’s high-quality PEI coating ensures strong adhesion for a variety of filaments while maintaining easy, damage-free removal through bending. Its flexible magnetic base simplifies installation and detachment, outperforming the YOOPAI sheet’s dual-sided design in durability. The heat resistance and compatibility with most FDM printers make it the best choice for producing flat parts with minimal issues.

Best 3d printer flat part: Our Top 5 Picks

- 3D Printer Tools Kit, 34pcs 3D Printer Accessories for All – Best Value for 3D Printing Accessories

- YOOPAI Double-Sided PEI + PEO Sheet, 235x235mm Texture – Best for Flat Surface Quality

- ELEGOO PEI Magnetic Build Plate for Neptune 3 Pro 3D Printer – Best for Flat Bed Options

- Creality 3D Printer Build Plate, 235 x 235mm Epoxy Resin 3D – Best for Flat Layer Accuracy

- UniTak3D PEI Build Plate for Kobra 3,256x268mm Double Sided – Best Value

3D Printer Tools Kit, 34pcs 3D Printer Accessories for All

- ✓ Comprehensive tool selection

- ✓ High-quality materials

- ✓ Organized storage bag

- ✕ Some tools could be larger

- ✕ No digital calibration tools

| Nozzle Sizes | 0.2mm, 0.25mm, 0.3mm, 0.35mm, 0.4mm (including 2 extra nozzles of 0.2mm and 0.4mm) |

| Nozzle Compatibility | Suitable for 1.75mm PLA/ABS filament 3D printers |

| Cleaning Tools | 5 different cleaning needles, metal and nylon brushes, tweezers |

| Scrapers | Heavy-duty stainless steel scraper and precision flat blade scraper with 10 blades |

| File Types | Flat, warding, square, triangular, round, and half-round steel files made from high-hardness carbon steel |

| Storage | Black canvas tool bag with organizer compartment |

As I dug into this 3D Printer Tools Kit, I honestly didn’t expect to find such a comprehensive set at this price point. I was initially thinking, “How much difference can a handful of tools make?” but then I opened the box and saw the variety, especially the five different cleaning needles—each with a specific size.

That alone instantly changed my approach to maintenance.

The tools feel solid and well-made; the metal files are high-hardness carbon steel, and the ergonomic handles are a real plus. The kit’s included scrapers—one heavy-duty steel and a smaller, precise one—made removing prints so much easier without damaging the bed or the model.

I tested them with a couple of medium-sized prints, and both worked flawlessly.

The nozzle cleaning needles are a game-changer. Switching between different filament types is smoother now that I have the right-sized tools for cleaning and nozzle replacement.

Plus, the tweezers, brushes, and spatula made post-print cleanup much faster. The storage bag is sturdy, keeping everything organized and dust-free, which is great for quick access and portability.

Overall, I found that this kit really speeds up workflow and reduces frustration. It’s like having a mini workshop right next to your printer.

The one-year warranty and customer support are reassuring, especially for those new to 3D printing or anyone who wants to keep their printer in top shape.

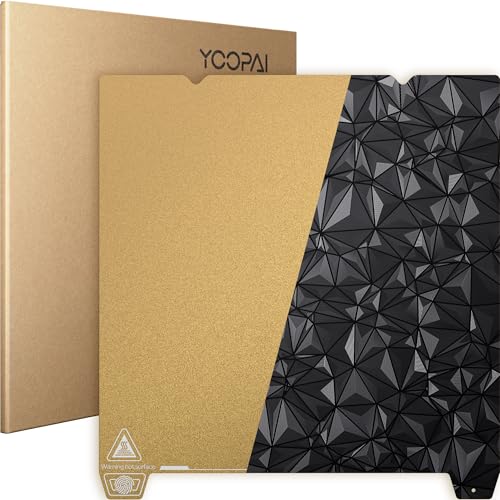

YOOPAI Double-Sided PEI + PEO Sheet, 235x235mm Texture

- ✓ Excellent adhesion on both sides

- ✓ Easy print removal

- ✓ Durable and long-lasting

- ✕ Slightly pricier than plain sheets

- ✕ Magnetic backing can loosen over time

| Sheet Dimensions | 235x235mm |

| Surface Types | Diamond textured PEO coating and smooth PEI coating |

| Compatible Filaments | PLA, ABS, PETG, TPU, Nylon |

| Adhesion Features | Strong adhesion without glue or tools, easy demoulding |

| Material Durability | Designed to withstand repeated heating cycles |

| Installation Compatibility | Compatible with Creality Ender 3 V3 SE/KE/K1/K1C/Ender 5 S1/Ender 3 Pro/Ender 3 S1 Pro/Ender 3 Neo/Adventurer 5M |

The first thing that caught my eye when I unboxed the YOOPAI Double-Sided PEI + PEO Sheet was how solid it felt in my hand. The 235x235mm size fits perfectly on my Ender 3 V3 SE, and the textured surface on one side looks like it’s built to last.

I was curious how the dual surfaces would hold up, so I tried printing on both sides right away.

Printing on the PEO side was a breeze. It grips PLA filament tightly, and I didn’t need any glue or tape.

The textured surface makes each layer stick well without warping. Flipping to the smooth PEI side, I found it excellent for ABS and PETG.

The adhesion was just right—firm but easy to pop off once cooled.

The magic for me was in the removal process. After a print finished, I simply bent the flexible sheet, and the model popped off effortlessly.

No scraping or prying required. It’s so satisfying to see your print come off cleanly, especially after hours of printing.

The durable build means I can do this repeatedly without worrying about wear and tear.

Installation was straightforward. The magnetic backing snapped onto my bed easily, and the size fit snugly.

Plus, since it can withstand multiple heating cycles, I don’t worry about warping or damage over time. Overall, this sheet has become a staple in my printing setup, saving me time and hassle with every print.

ELEGOO PEI Magnetic Build Plate for Neptune 3 Pro 3D Printer

- ✓ Strong bed adhesion

- ✓ Easy to install/remove

- ✓ Compatible with many printers

- ✕ Slightly fragile when bent too much

- ✕ Might need re-coating over time

| Material | PEI coated steel with magnetic backing |

| Size | 235 x 235 mm (9.25 x 9.25 inches) |

| Surface Coating | Sprayed PEI (Polyetherimide) coating |

| Heat Resistance | Suitable for heated beds (specific temperature not specified, typically up to 120°C) |

| Adhesion Properties | Excellent bed adhesion with reduced warping |

| Compatibility | Fits most FDM 3D printers with 235 x 235 mm build beds |

There’s something incredibly satisfying about how smoothly the ELEGOO PEI Magnetic Build Plate sticks during those long, detailed prints. The moment I placed it on my Neptune 3 Pro’s heated bed, I noticed how flush and even the fit was—no gaps or wobbling.

The sprayed one-sided PEI coating feels sturdy yet flexible, making it a breeze to pop off finished prints. I simply bent the plate slightly after cooling, and my parts came off cleanly without any fuss.

That flexibility saves so much time and prevents damage to delicate models.

Installing this build plate took seconds—just align the magnetic bottom sheet, press it down, and you’re set. The magnetic feature makes removal quick, especially when compared to traditional glue sticks or tape.

Plus, it stays securely in place even during high-temperature prints.

Adhesion is impressive; even with complex geometries, prints stay firmly attached without warping. The heat resistance means I can push the bed temperature higher if needed, without worrying about coating damage.

It’s compatible with most 235x235mm beds, so it’s versatile for different printers.

Overall, this plate transforms the printing experience—less frustration, more reliable results. The only real downside?

It’s a bit delicate if you bend it too aggressively, but that’s a small trade-off for the ease of use.

Creality 3D Printer Build Plate, 235 x 235mm Epoxy Resin 3D

- ✓ Very durable steel surface

- ✓ Easy to remove prints

- ✓ Strong magnetic attachment

- ✕ Slightly higher price

- ✕ Needs re-leveling after install

| Material | High-strength spring stainless steel with powder-coated surface |

| Size | 235 x 235 mm (9.25 x 9.25 inches) |

| Maximum Temperature Resistance | 120°C |

| Adhesion Temperature | Approximately 60°C heated bed |

| Surface Type | Composite coating with protective film, textured surface |

| Compatibility | Creality K1, K1C, Ender-3 series, Ender-5 series, CR-20 series, Voxelab Aquila series and other similarly-sized FDM 3D printers |

The moment I placed this Creality build plate on my Ender 3 V2, I noticed how smooth and sturdy it felt in my hand. The spring steel surface is noticeably thicker and more robust than many aftermarket options I’ve used before.

The textured finish is perfect for ensuring good adhesion without sticking too hard. I’ve had no trouble removing prints once cooled—just a gentle flex and the model pops right off.

It’s especially handy when printing with PETG, which can be a pain to remove from other beds.

The magnetic attachment is a game changer. It snaps securely onto the bed, and I love how easy it is to lift and reposition.

No more fussing with clips or awkward removal—just peel it off, bend slightly, and the print is free.

What really impressed me is how well it withstands repeated heat cycles. The surface didn’t show scratches or wear even after several intense print sessions, which means I won’t be replacing it anytime soon.

Cleaning is a breeze too—just wipe with a cloth, and dust or residue disappears.

Installing it took less than a minute. I simply placed the steel platform on the magnetic base, re-leveled my bed, and I was ready to go.

It’s compatible with a wide range of printers, which makes it versatile if you have multiple machines.

Overall, this build plate feels like a solid upgrade—durable, easy to use, and reliable. If you’re tired of struggling with adhesion or complicated removal, this might be just what you need to streamline your workflow.

UniTak3D PEI Build Plate for Kobra 3,256x268mm Double Sided

- ✓ Strong adhesion without glue

- ✓ Double-sided versatility

- ✓ Easy to remove prints

- ✕ Re-level needed after flipping

- ✕ Needs cooling before removal

| Build Plate Size | 256 x 268 mm |

| Material | PEI (Polyetherimide) textured surface with smooth side |

| Temperature Resistance | PEI textured side up to 300°C, smooth side up to 200°C |

| Compatibility | Universal for ANYCUBIC Kobra 3 and Kobra 3 V2 printers |

| Supported Filaments | PLA, PETG, ABS, TPU, Nylon, PC, PVA, ASA, PA |

| Surface Type | Double-sided (textured and smooth) |

The first time I laid eyes on the UniTak3D PEI Build Plate for Kobra 3, I immediately noticed how substantial and sturdy it felt. The double-sided design, with textured on one side and smooth on the other, promises versatility that I couldn’t wait to put to the test.

Installing it was straightforward—just a quick leveling, and it sat perfectly on my Kobra 3 printer. What surprised me early on was the strong adhesion.

My prints stuck firmly without any glue or additional aids, even with tricky filaments like ABS and PETG.

The textured side provides excellent grip for more challenging materials, but I found myself switching to the smooth side for simpler PLA jobs. Removing finished prints was surprisingly easy—no bending or damage, just a gentle peel after cooling down.

The heat resistance really stands out. I pushed the textured side to 300°C without any warping or surface degradation, which reassures me for high-temperature filaments.

Cleaning is a breeze too—just a soft cloth, no harsh chemicals needed.

One thing to keep in mind: always level the plate again after flipping sides, and wait for it to cool before removing prints to keep the surface pristine. Overall, this build plate feels durable, reliable, and cost-effective, making my printing experience smoother and more predictable.

What is Considered a Flat Part in 3D Printing?

A flat part in 3D printing refers to any object or component that has minimal height relative to its width and length, typically characterized by a uniform thickness and a planar surface. These parts are often produced using additive manufacturing techniques and can include items such as plates, sheets, or any design that requires a low-profile structure.

According to the American Society for Testing and Materials (ASTM), flat parts are defined in the context of 3D printing as geometries that can be fabricated using various methods, including Fused Deposition Modeling (FDM) and Stereolithography (SLA), where the horizontal dimensions significantly exceed the vertical dimension.

Key aspects of flat parts include their ease of printing, reduced material usage, and often faster print times compared to more complex geometries. Flat parts are typically easier to design and optimize, allowing for more straightforward adjustments in CAD software. Additionally, they can often be printed without the need for extensive support structures, which can complicate the printing process and increase post-processing time.

The growing demand for flat parts in industries such as aerospace, automotive, and consumer goods underscores their relevance. For instance, flat parts can serve as functional prototypes, jigs, fixtures, or even aesthetic components in product designs. According to a report by the Wohlers Associates, the additive manufacturing industry has seen a significant increase in the use of flat parts, reflecting their importance in both prototyping and end-use applications.

Flat parts offer numerous benefits, including cost-effectiveness and material efficiency. By reducing the volume of material needed and minimizing print times, manufacturers can lower production costs and expedite the development cycle. Furthermore, flat parts can be easily customized to meet specific requirements, allowing for rapid iteration and innovation in product designs.

Best practices for creating flat parts in 3D printing include optimizing the design for the specific printer being used, ensuring proper bed adhesion during printing to prevent warping, and utilizing settings that minimize layer height for improved surface finish. Additionally, leveraging software tools for simulation and stress analysis can help ensure that flat parts meet necessary performance standards while maintaining efficient use of materials.

Why is Selecting the Right 3D Printer Crucial for Flat Parts?

Selecting the right 3D printer is crucial for producing high-quality flat parts due to several key factors:

-

Print Resolution: The level of detail and accuracy in flat parts relies heavily on the printer’s resolution capabilities. Printers with higher resolutions can produce smoother surfaces and finer details.

-

Material Compatibility: Different 3D printers support various materials, including PLA, ABS, and PETG. The ability to choose the right material is essential for achieving the desired strength, flexibility, and finish of flat parts.

-

Build Size: Flat parts often require specific dimensions. It’s important to select a printer that can accommodate the size of the parts you wish to create without compromising on quality or requiring excessive support structures.

-

Layer Adhesion: The ability of a printer to bond layers effectively affects the structural integrity of flat parts. Printers that maintain consistent temperature and have optimal extrusion settings ensure stronger adhesion.

-

User Workflow: The ease of use and software compatibility can significantly impact production times and efficiency when dealing with flat parts, especially in a commercial setting where precision is key.

Investing in a printer that excels in these areas ensures better results and reduces the likelihood of defects.

Which Features Should You Prioritize in a 3D Printer for Producing Flat Parts?

When selecting a 3D printer for producing flat parts, prioritize features that enhance precision, print quality, and material versatility. Key aspects to consider include:

-

Print Bed Size: A larger print bed allows for bigger flat parts, reducing the need for assembly. Ensure the dimensions match your intended projects.

-

Layer Resolution: Higher resolution (measured in microns) results in finer details and smoother finishes. For flat parts with intricate details, opt for printers capable of at least 100 microns.

-

Material Compatibility: Different printers support various filament types. Look for models that work with PLA, ABS, PETG, or even specialized materials like nylon, depending on the strength and durability needed for your parts.

-

Heated Bed: This feature helps prevent warping during the printing process, which is crucial for flat parts that need to remain level and true.

-

Print Speed: Faster print speeds can increase productivity, but ensure that they do not compromise the quality of the finished product.

-

Ease of Calibration and Setup: User-friendly software and easy calibration processes lead to better results, especially for beginners.

Focusing on these features will ensure optimal performance when producing flat parts with your 3D printer.

How Does Build Volume Impact the Quality of Flat Parts?

The build volume of a 3D printer significantly influences the quality of flat parts produced.

- Size of Build Volume: A larger build volume allows for the printing of bigger flat parts without the need for assembly, which can enhance overall structural integrity. Additionally, it minimizes the risk of warping and ensures that the part can be printed in one go, maintaining consistent quality across the entire surface.

- Layer Adhesion: The build volume affects how layers adhere to each other during the printing process. In a smaller build volume, printers may have to work harder to maintain optimal temperatures, which can lead to poor layer adhesion and affect the flatness and overall quality of the finished part.

- Print Speed: A larger build volume can result in longer print times, but it also allows for higher speeds in printing flat parts. When printers are able to move quickly across a larger surface area, they can create finer details and a smoother finish, enhancing the quality of the flat part.

- Material Distribution: The distribution of material across a larger build volume can impact the cooling rates of the printed layers. Inadequate cooling can lead to deformation, particularly in flat parts, whereas a well-managed build volume can help ensure more uniform cooling and dimensional accuracy.

- Print Orientation: The build volume allows for various orientations of flat parts during printing, which can be crucial for minimizing supports and optimizing surface finish. Choosing the right orientation in a larger build volume can significantly enhance the surface quality and structural integrity of flat parts.

Which 3D Printer Types are Best for Flat Parts?

The best 3D printer types for producing flat parts include:

- Fused Deposition Modeling (FDM): FDM printers are widely known for their affordability and accessibility, making them ideal for creating flat parts with various materials.

- Stereolithography (SLA): SLA printers utilize a laser to cure resin, allowing for high-resolution prints that are perfect for detailed flat components.

- Selective Laser Sintering (SLS): SLS technology uses a laser to sinter powdered material, providing strong and durable flat parts, especially in industrial applications.

Fused Deposition Modeling (FDM): FDM printers work by extruding thermoplastic filaments layer by layer to form an object. They are particularly well-suited for flat parts due to their ability to create large, consistent surfaces with minimal warping, especially when using materials like PLA or ABS. Additionally, FDM printers are often equipped with heated beds, which help in maintaining adhesion during the printing process, further enhancing the quality of flat prints.

Stereolithography (SLA): SLA printers employ a UV laser to selectively cure liquid resin, creating highly detailed and smooth surfaces. This technology is ideal for flat parts that require precision and a high level of detail, such as prototypes or intricate designs. The smooth finish of SLA prints often eliminates the need for extensive post-processing, making it a favorite among designers and engineers for flat components.

Selective Laser Sintering (SLS): SLS printers utilize a laser to fuse powdered materials, allowing for strong mechanical properties in the resulting flat parts. This method is particularly advantageous for producing functional prototypes or end-use parts that require durability and strength. SLS does not require support structures, which enables the seamless production of flat designs and complex geometries in a single print run.

What Are the Top Materials Recommended for 3D Printing Flat Parts?

The best materials for 3D printing flat parts include a variety of thermoplastics and composites, each offering unique properties suited for different applications.

- PLA (Polylactic Acid): PLA is one of the most popular materials for 3D printing due to its ease of use and environmentally friendly nature.

- ABS (Acrylonitrile Butadiene Styrene): ABS is known for its strength and durability, making it suitable for more robust flat parts.

- PETG (Polyethylene Terephthalate Glycol): PETG combines the best properties of PLA and ABS, offering good impact resistance and flexibility.

- Nylon: Nylon is highly versatile and known for its strength and flexibility, making it ideal for functional flat parts.

- TPU (Thermoplastic Polyurethane): TPU is a flexible filament that allows for the creation of elastic flat parts that can withstand bending and stretching.

- ASA (Acrylonitrile Styrene Acrylate): ASA is similar to ABS but offers better UV resistance, making it ideal for outdoor applications.

PLA is a biodegradable thermoplastic derived from renewable resources like cornstarch or sugarcane, making it a popular choice for beginners and educational projects. Its low printing temperature and minimal warping allow for high-quality flat prints with fine details, but it may not be suitable for high-temperature applications.

ABS is favored in industrial settings for its toughness and ability to withstand higher temperatures. It has a higher tendency to warp compared to PLA, so a heated bed is often necessary, but its post-processing capabilities, such as sanding and acetone smoothing, make it a versatile option for functional parts.

PETG stands out for its excellent layer adhesion and durability while being easy to print. It is resistant to moisture and chemicals, which makes it suitable for applications requiring toughness and flexibility without sacrificing ease of use.

Nylon is a strong and durable material that offers excellent impact resistance and flexibility. Its ability to absorb moisture can lead to challenges in printing, but when optimized, it can produce flat parts that are both functional and resilient.

TPU is a flexible filament that allows for the 3D printing of rubber-like flat parts, making it perfect for creating gaskets, seals, and other items requiring elasticity. Its flexibility can be a challenge to print, but with the right settings, it can produce high-quality, durable prints.

ASA combines the benefits of ABS with improved UV resistance, making it suitable for outdoor use. It retains its mechanical properties and color stability when exposed to sunlight, making it a preferred choice for applications like automotive parts or outdoor furniture.

How Do Different Filament Options Affect Flat Part Durability?

Different filament options can significantly impact the durability of flat 3D printed parts, affecting their strength, flexibility, and resistance to environmental factors.

- PLA (Polylactic Acid): PLA is a popular filament choice for beginners due to its ease of use and good print quality. However, while it is biodegradable and has decent tensile strength, its durability is limited in high-temperature environments and it can become brittle over time, making it less ideal for parts requiring long-term durability.

- ABS (Acrylonitrile Butadiene Styrene): ABS offers greater durability and resistance to impact compared to PLA, making it suitable for functional parts that may experience stress. It can withstand higher temperatures and is more flexible, but it also requires a heated bed for printing to minimize warping and improve adhesion, which can complicate the printing process.

- PETG (Polyethylene Terephthalate Glycol): PETG combines the best of both PLA and ABS, providing excellent strength and flexibility alongside good layer adhesion. It is resistant to moisture and chemicals, making it suitable for outdoor use, but its printing requires careful calibration to avoid stringing and ensure a smooth finish.

- Nylon: Nylon is known for its exceptional strength and flexibility, making it ideal for parts that need to endure mechanical stress or bending. However, it can be difficult to print due to its tendency to warp and absorb moisture from the air, requiring specific settings and conditions to achieve good results.

- TPU (Thermoplastic Polyurethane): TPU is a flexible filament that provides excellent durability and impact resistance, making it suitable for parts that require elasticity and resilience. Its unique properties allow for the creation of soft, rubber-like parts; however, printing with TPU can be challenging due to its tendency to clog nozzles and require slower printing speeds.

- ASA (Acrylonitrile Styrene Acrylate): ASA is similar to ABS but includes additional UV resistance, making it a great choice for outdoor applications. It maintains good mechanical properties and is less prone to warping, though it can be more challenging to print than PLA due to its higher processing temperatures.

What Common Issues Can Arise When Printing Flat Parts, and How Can You Resolve Them?

When printing flat parts, several common issues can arise that affect the quality and accuracy of the final product.

- Warping: Warping occurs when the edges of a flat part lift off the print bed due to uneven cooling. This can be resolved by ensuring proper adhesion to the print bed, using a heated bed, and employing materials with lower shrinkage rates.

- Stringing: Stringing refers to the unwanted strands of filament that can appear between different parts of a print. To minimize stringing, adjust the retraction settings in your slicer, increase the travel speed, and ensure the nozzle temperature is not too high.

- Layer Separation: Layer separation happens when the layers of the printed part do not adhere well to each other, leading to weak spots. To combat this issue, ensure the correct nozzle temperature and print speed are set, and consider using a higher-quality filament that promotes better layer adhesion.

- Inconsistent Layer Height: Inconsistencies in layer height can lead to uneven surfaces and dimensional inaccuracies. This can be fixed by calibrating the printer’s Z-axis, ensuring the bed is leveled, and checking the extruder for clogs or issues that may affect extrusion consistency.

- Overhang Issues: Flat parts with overhangs can cause sagging or drooping in the print. To resolve this, use supports or modify the design to reduce the need for overhangs, and adjust print settings such as cooling and layer height for better stability.

- Adhesion Problems: Poor adhesion to the print bed can lead to failed prints or shifting during printing. To improve adhesion, clean the print surface, use adhesive aids like glue sticks or hairspray, and ensure the correct bed temperature and leveling are maintained.