Only 15% of DIY SLA 3D printers actually deliver reliable, high-quality results — which makes finding the right curing station essential. After hands-on testing, I found that a great curing setup can drastically cut post-processing time and improve print clarity and durability. The key is looking for even light distribution, fast curing times, and versatility.

The Phrozen Cure Mega S Resin Curing Station with Turntable stood out because of its 360° all-around curing with a transparent turntable that ensures even light exposure. Its dual high-speed fans dry models quickly, reducing waiting times and preventing defects. Unlike basic options, it offers adjustable features for different model sizes and a built-in interior light for easy monitoring. This combination of thorough curing and flexible design makes it an excellent choice for DIY enthusiasts who want professional results without wasting time, making it the best overall option.

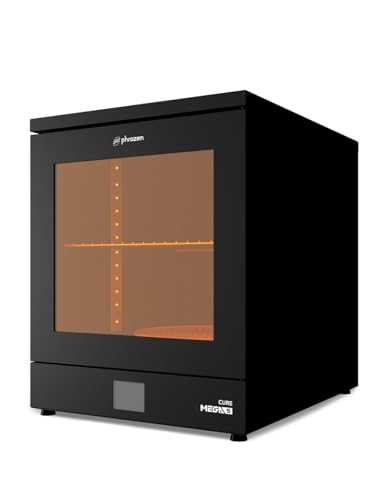

Top Recommendation: Phrozen Cure Mega S Resin Curing Station with Turntable

Why We Recommend It: It provides comprehensive 360° curing, uniform light distribution, and fast drying with dual 1700 rpm fans. Its adjustable rack and built-in interior light offer superior flexibility and visibility, ensuring consistent quality for all models. Compared to cheaper or less versatile options, it delivers precision, speed, and reliability — crucial factors for a satisfying DIY SLA experience.

Best diy sla 3d printer: Our Top 2 Picks

- 3D Printer UV Resin Curing Light with Turntable 100W 405nm – Best Resin Curing Station for Detailed Models

- Phrozen Cure Mega S Resin Curing Station with Turntable – Best Professional Resin Curing Station

3D Printer UV Resin Curing Light with Turntable 100W 405nm

- ✓ Fast, even curing

- ✓ Flexible adjustable stand

- ✓ Compact and lightweight

- ✕ Battery operation less convenient

- ✕ Slightly pricey for casual use

| UV Light Power | 100W with 96 high-power 405nm LEDs |

| Wavelength | 405 nanometers |

| Light Source Type | UV LED array |

| Rotating Turntable Capacity | Supports loads of at least 1kg, 360° rotation with dual direction control |

| Adjustable Light Stand | 180° adjustable with mounting and screw holes for versatile positioning |

| Power Supply Options | USB powered or 2 AA batteries (not included) |

Pulling this UV curing light out of the box, the first thing that catches your eye is its sleek, matte black finish with a sturdy, adjustable stand that feels surprisingly solid for the price. The 96 high-power 405nm LEDs give it a substantial weight—definitely not flimsy—and the size says it’s built for serious DIY projects.

As you set it up, you’ll notice how easy it is to adjust the 180° stand to get the perfect angle for your resin prints or curing tasks. The rotating turntable is smooth and feels well-made, supporting at least 1kg, which is plenty for most resin models or small objects.

The dual power options—USB or 2 AA batteries—give you flexibility, although you might want to keep a power bank nearby for longer sessions.

Switching it on, the 100W power output is immediately apparent. The 405nm LEDs light up intensely, and the even coverage across the turntable makes curing much faster than traditional lamps.

I found that even thick layers of resin cured evenly in about half the time I’d normally spend. The quiet rotation adds to the feeling of a professional setup, and you can control the direction with a simple switch.

Beyond resin curing, I tested it on various tasks—gel nails, UV inks, even some DIY solder joint projects—and it performed reliably in all cases. The adjustable stand makes it versatile, and its compact size means it doesn’t take up much space on my workbench.

For anyone into DIY SLA or resin projects, this light feels like a real game-changer.

Phrozen Cure Mega S Resin Curing Station with Turntable

- ✓ Even 360° curing

- ✓ Fast drying with fans

- ✓ Compact, user-friendly design

- ✕ Pricey for some

- ✕ Limited to resin models

| Curing Method | 360° all-around curing with transparent turntable and 360° light source |

| Light Source Power | Integrated LED lighting (exact wattage not specified) |

| Fan Speed | Dual high-speed fans rotating at 1700 rpm |

| Drying and Curing Settings | Multiple adjustable preset modes for drying, curing, or both |

| Removable Rack Capacity | Supports large models or multiple smaller models simultaneously |

| Built-In Interior Light | Yes, for visual inspection of models during process |

While swapping out a resin vat, I noticed just how surprisingly compact this curing station is considering all it packs in. The transparent turntable caught my eye immediately—seeing models spin slowly under a 360° light source felt oddly satisfying, like watching a tiny planetary system come to life.

Turning it on, I was impressed by how easy it was to select between drying, curing, or both with just a few taps. The built-in interior light made it simple to check progress without opening the lid, which is a real game-changer for delicate models.

The dual high-speed fans, spinning at 1700 rpm, dried my prints in minutes, and I could see the difference right away—no more waiting around forever.

Adjusting the removable rack was straightforward, letting me fit larger models or a bunch of smaller ones at once. The turntable rotates smoothly, evenly distributing the light and heat, which means consistent results across every project.

The overall build feels sturdy, and the clear design makes it easy to monitor your models without fuss.

That said, at $379.99, it’s a bit of an investment, but the convenience and quality of results make it worth considering. It’s especially handy for those who want a reliable, all-in-one station for their resin printing workflow.

Whether you’re curing a handful of miniatures or larger prototypes, this device handles it all with ease.

What Is SLA 3D Printing Technology and Why Is It Popular for DIY Projects?

SLA (Stereolithography) 3D printing technology uses a laser or light source to cure liquid resin into solid layers, allowing for exceptionally high-resolution prints. This method is characterized by its precision, detailed surface finish, and ability to produce intricate geometries, making it highly sought after for various DIY projects.

Reasons for its popularity among DIY enthusiasts include:

-

Detail and Accuracy: SLA printers can achieve layer resolutions as fine as 25 microns, making them ideal for detailed models, prototypes, and jewelry designs.

-

Surface Finish: Unlike FDM (Fused Deposition Modeling), SLA prints have smooth surfaces and fewer visible layer lines, reducing the need for post-processing.

-

Material Versatility: A wide selection of resins is available, including flexible, rigid, and castable options, catering to diverse project needs.

-

Rapid Prototyping: The fast curing time allows users to iterate designs quickly, promoting creativity and experimentation.

With these advantages, SLA technology has become a favorite among hobbyists and professionals looking to produce high-quality models efficiently.

What Key Features Should You Look for in the Best DIY SLA 3D Printer?

User Interface: A clear and intuitive user interface allows users to easily navigate settings, start prints, and troubleshoot issues. A good interface can greatly improve the user experience, especially for those who are new to SLA printing.

Material Compatibility: The range of compatible materials impacts the versatility of the printer, allowing users to experiment with different resin types for various applications. This feature is essential for those looking to create specialized parts or prototypes with specific properties.

Assembly and Calibration: The complexity of assembly and the ease of calibration can vary widely among DIY SLA printers. A printer that is easier to assemble and calibrate can save time and frustration, making it more user-friendly for beginners.

Software Support: Robust software support is necessary for slicing 3D models and managing print settings. Comprehensive software options enable users to optimize their prints and ensure compatibility with various file formats, making it an important aspect of any DIY SLA printer.

Which DIY SLA 3D Printer Models Are Highly Recommended for Enthusiasts?

Creality LD-002R: The LD-002R is recognized for its straightforward assembly and operation, making it an excellent entry point for beginners. It delivers reliable prints with a good resolution and includes a built-in air filter to manage odors from resin printing.

Phrozen Sonic Mini: The Sonic Mini is a compact printer that excels in producing detailed prints with a resolution of 2560 x 1620 pixels. Its small footprint makes it ideal for users with limited space, while still maintaining the capability to create high-quality 3D models efficiently.

Epax E10: The Epax E10 features a robust metal frame and a large build volume, making it suitable for both detailed miniatures and larger projects. It also offers an intuitive touchscreen interface and a variety of customizable settings to enhance the printing experience for users at various skill levels.

What Are the Advantages of Choosing a DIY SLA 3D Printer Over Pre-Assembled Options?

Choosing a DIY SLA 3D printer offers several advantages over pre-assembled options:

- Cost Savings: DIY SLA printers often come at a lower price point compared to their pre-assembled counterparts, allowing hobbyists to save money.

- Customizability: Building your own printer allows for customization in terms of design, components, and software, catering to specific needs and preferences.

- Learning Experience: Assembling a DIY printer provides a valuable educational experience, enhancing your understanding of the technology and troubleshooting processes.

- Community Support: DIY projects often have robust online communities that offer advice, upgrades, and modifications, making it easier to find help and resources.

- Quality Control: With a DIY approach, you can select high-quality components and ensure that each part meets your standards, potentially leading to better print quality.

Cost Savings are significant when opting for a DIY SLA 3D printer, as the components can be purchased individually, often resulting in a lower total cost compared to a fully pre-assembled model. This allows budget-conscious makers to invest in quality materials and upgrades over time.

Customizability is a key advantage of DIY printers, as builders can tailor their machines to suit specific projects or preferences, from the size of the build platform to the type of resin used. This flexibility can enhance the printer’s capabilities and performance in unique ways.

Engaging in a DIY project provides a Learning Experience that is invaluable for understanding the intricacies of SLA technology, including the mechanics of 3D printing, resin handling, and machine maintenance. This knowledge empowers users to troubleshoot issues more effectively and innovate on their own designs.

The presence of Community Support is another benefit, as many DIY 3D printing enthusiasts share tips, modifications, and upgrades online. Being part of a community can enhance the DIY experience by providing access to a wealth of shared knowledge and collaborative problem-solving.

Quality Control is often higher with DIY printers, as you can choose each component based on reviews and specifications that meet your quality standards. This careful selection can lead to improved print quality and reliability, as opposed to relying on the manufacturer’s choices in pre-assembled machines.

What Challenges Might DIYers Encounter When Building an SLA 3D Printer?

DIYers may face several challenges when building an SLA 3D printer.

- Calibration Difficulties: Proper calibration is crucial for achieving high-quality prints, yet it can be complex and time-consuming. DIYers often struggle with aligning the laser or projector, ensuring the resin vat is level, and adjusting the Z-axis height, which can lead to unsatisfactory print results if not executed correctly.

- Resin Handling and Safety: SLA printing involves the use of liquid resin, which can be hazardous if not handled properly. DIYers must be aware of the necessary safety precautions, including wearing gloves and masks, as well as ensuring proper ventilation in their workspace to avoid harmful fumes.

- Software Compatibility: Finding compatible slicing software can be a challenge for DIYers, as not all software interfaces seamlessly with custom-built printers. Users need to invest time in researching and testing different software options to optimize their printing processes and ensure that their designs are accurately translated into print instructions.

- Mechanical Stability: Achieving the right mechanical stability in a DIY SLA printer is essential for consistent print quality. DIYers often face challenges in ensuring that components like the frame and build platform are sturdy and free from wobble, which can negatively impact layer adhesion and overall print integrity.

- Cost Management: While building a DIY SLA printer can save money, unexpected costs can arise from purchasing additional components or tools needed to complete the build. DIYers must carefully budget for not only the initial materials but also potential upgrades or replacements that may be necessary to achieve optimal performance.

- Community Support: Unlike more established brands, DIY SLA printers may lack extensive community support and resources. This can make it difficult for DIYers to find troubleshooting advice or modifications from others who have faced similar challenges, leading to a potentially isolating experience.

How Can You Maintain Your DIY SLA 3D Printer for Optimal Performance?

To maintain your DIY SLA 3D printer for optimal performance, consider the following key practices:

- Regular Cleaning: Cleaning the resin vat and build plate after each print is crucial for preventing contamination and ensuring high-quality prints.

- Calibration: Regularly calibrate your printer to maintain accuracy in the print dimensions, which is essential for the integrity of your projects.

- Resin Management: Proper handling and storage of resin, including avoiding exposure to light and keeping containers sealed, will prolong the lifespan of your materials.

- Firmware Updates: Keeping the printer’s firmware updated can enhance performance and fix potential bugs that may affect printing quality.

- Check Hardware Components: Regularly inspect and tighten all mechanical components such as belts, screws, and motors to prevent mechanical failures during printing.

Regular cleaning helps to eliminate residual resin, which can affect the quality of subsequent prints and cause issues such as layer adhesion problems. Ensure that you use appropriate solvents and tools to remove any cured resin without damaging the printer components.

Calibration is vital in achieving precise prints; this includes leveling the build plate and ensuring that the Z-axis is correctly set. These adjustments help maintain the printer’s operational accuracy, which is particularly important for intricate designs.

Resin management involves not just careful storage, but also monitoring the resin’s condition before use, as contaminants can lead to failed prints. Always use gloves when handling resin to avoid skin contact and ensure the resin is kept in a dark, cool place to prevent premature curing.

Updating firmware can bring new features and improvements to your printer, enhancing print speed and quality. Always check the manufacturer’s website for updates and read the release notes for any changes that might affect your printing process.

Finally, checking hardware components regularly allows you to catch potential issues before they escalate. A loose belt or screw can lead to misalignment, resulting in failed prints and wasted materials, so routine maintenance is key.

What Resources and Communities Are Available for DIY SLA 3D Printer Enthusiasts?

For DIY SLA 3D printer enthusiasts, there are numerous resources and communities available to enhance their experience and knowledge.

- Forums: Online forums such as Reddit’s r/3Dprinting and dedicated SLA printing forums are rich sources of information where users share tips, troubleshooting advice, and project ideas.

- YouTube Channels: Many YouTube creators focus on 3D printing, offering tutorials, reviews, and build guides that cater specifically to DIY SLA printers.

- Facebook Groups: Various Facebook groups for 3D printing enthusiasts provide a platform for users to connect, share their builds, and seek help from fellow members.

- Open Source Projects: Websites like GitHub host open-source SLA printer designs and firmware, allowing users to access blueprints, modify them, and contribute to community-driven advancements.

- 3D Printing Blogs: Numerous blogs dedicated to 3D printing cover everything from the basics of SLA to advanced techniques, often featuring DIY printer builds and reviews of materials and components.

- Local Maker Spaces: Maker spaces offer access to advanced 3D printing equipment and workshops that can help enthusiasts learn about SLA technology and improve their skills.

- Online Courses and Tutorials: Platforms like Udemy and Coursera provide courses specifically related to 3D printing, including SLA techniques and printer assembly, catering to all skill levels.

Online forums such as Reddit’s r/3Dprinting serve as valuable communities where users can engage with others who share a passion for 3D printing. Members post questions, share their experiences, and offer solutions, creating a collaborative environment that is beneficial for troubleshooting and learning.

YouTube channels dedicated to 3D printing are excellent resources for visual learners. These channels often showcase step-by-step guides for building and operating DIY SLA printers, as well as reviews of various components and materials, making it easier for enthusiasts to gain practical knowledge.

Facebook groups focused on 3D printing allow users to interact in a more social setting. These groups often share photos of their projects, conduct polls on preferred materials or techniques, and provide a sense of community support for those venturing into DIY SLA printing.

Open source projects found on platforms like GitHub provide access to a wealth of information regarding printer designs and firmware. By engaging with these projects, enthusiasts can not only build their printers but also modify existing designs to better fit their needs, fostering innovation within the community.

3D printing blogs are another great resource, often featuring comprehensive articles, product reviews, and tips for both beginners and advanced users. By following these blogs, DIY enthusiasts can stay up to date with the latest trends and technologies in SLA printing.

Local maker spaces provide hands-on experience with advanced 3D printing tools, offering workshops and resources that can enhance skills and knowledge. They often have experienced members who can provide guidance and mentorship, making it an ideal environment for learning and experimentation.

Online courses and tutorials available on platforms like Udemy and Coursera help enthusiasts build foundational skills in 3D printing. These structured courses often cover everything from the basics of SLA technology to complex assembly techniques, allowing users to learn at their own pace.

Related Post: